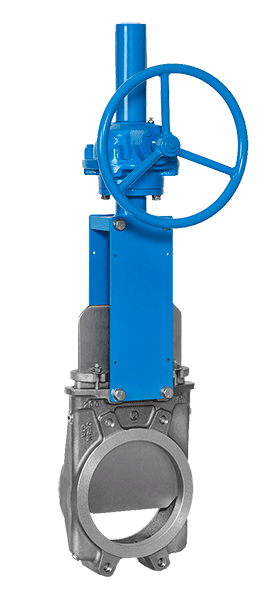

KNIFE GATE VALVES

T400 – SILO TYPE

The model 400 knife gate valve is a unidirectional wafer monoblock valve designed for industrial general service. Mainly used in bulk handling applications, discharge of powders and solids as OFF seat position (prevent solid accumulation in the seat area). Low pressure duty in solid discharge lines.

Applications: Pulp and Paper, Power generation, Water and Waste Water, Powder and Bulk Handling, Mining, Chemical, Food and Beverage.

- The special design of the body allows for easy passage of the fluid and makes it ideal for use as silo discharge valve.

- The valve is normally installed in the reverse position (seat upstream OFF seat) in order to avoid problems like solid accumulation, seat wear, difficult closing…

- Flushing holes (x4) integrated on the body as standard. These purge port allow internal cleaning of the valve and avoid solids trapping.

- Directional arrow in the body showing correct mounting position.

- DIR 2006/42/CE (machinery)

- DIR 2014/68/EU (PED) Fluid Group 1(b), 2 (Cat. I. mod. A)

- DIR 2014/34/EU (ATEX) Area 2&22

| FLANGE CONNECTION |

|

| SIZES & PRESSURES |

|

| TIGHTNESS |

|

| MATERIALS | BODY GG25, GGG40, A216 WCB, CF8 (AISI304), CF8M (AISI316), CF3M (AISI316L), 254SMO, 654SMO, AISI310, AISI904, DUPLEX SAF2205, SUPERDUPLEX SAF2507, AISI316Ti. SEAT EPDM, NITRILE (NBR), SILICONE, VITON, GRAPHITE, FLUCAST, PTFE. GATE AISI304L, AISI316L, 254SMO, HARDOX, AISI310, AISI904L, DUPLEX SAF2205, SUPERDUPLEX SAF2507, AISI316Ti. PACKING SYNT+PTFE, Pure PTFE, GRAPHITE, CERAMIC, Greased COTTON. |

| ACTUATORS | Manual, pneumatic, hydraulic, electric, gear box, hand lever, square end, chain-wheel, pneumatic with security hand wheel, pneumatic with security gear box. |

| ACCESSORIES AND OPTIONS | Limit switches, proximity sensors, solenoid valves, positioner 4/20mA, sleeves, locking devices, extension, regulation v-ports, cleaning holes, bonnet, etc. |

Downloads

Contact us

"*" indicates required fields